Technical InformationMolding Technology

Molding Process for TELENE®1600/1700 series

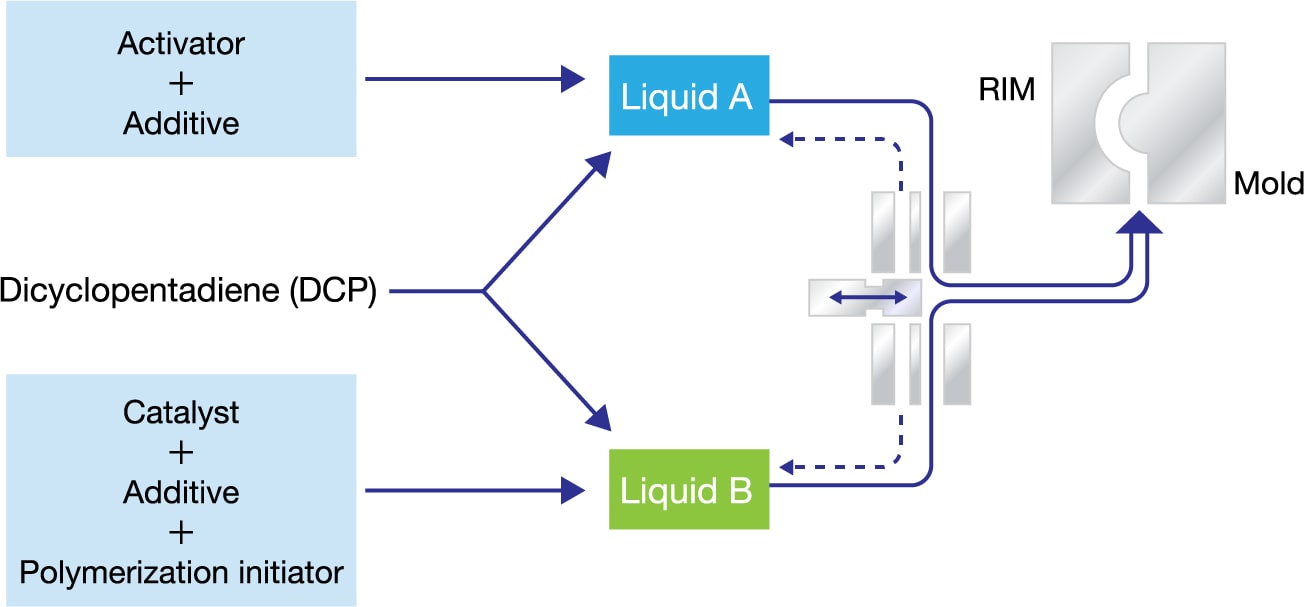

Reaction injection molding (RIM) is used for TELENE®1600/1700 series. RIM essentially involves a

two-liquid system: liquid A is dicyclopentadiene (DCP) with a catalyst activator and additive, and liquid

B is DCP with a catalyst, additive, and polymerization initiator.

Liquids A and B are pumped through pipes into a mold. They are impingement-mixed at an even volume rate

using a mixing head located at the bottom of the mold and then injected into the mold (3~5kgf/cm2).

Once liquids A and B are impingement-mixed, the catalyst and catalyst activator initiate a chemical

reaction that completes inside the mold in only a few minutes. The reaction generates heat and the molded

product is heated to nearly 200°C; therefore, it should be allowed to cool to about 100°C before being

removed. The entire process, from injecting liquids A and B to removing the molded product, is completed

in only about five minutes.

The DCP-RIM process is suitable for manufacturing large-scaled molded products with complex shapes in

a very short period and offers remarkable energy saving advantages. TELENE® is an environmentally sound

olefin thermosetting resin with well-balanced properties that respond to today’s need.

Only available in Japanese